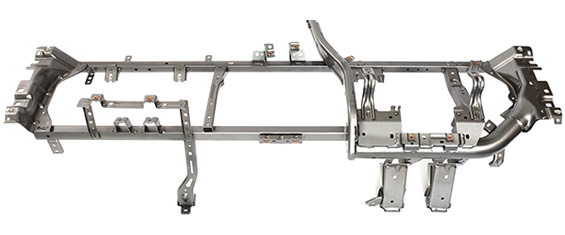

PROTOTYPE MANUFACTURING

Technique, Inc. is an industry leader in producing high-quality prototype metal stampings, bent tubing and laser cut tubing accurately in the fastest lead times possible.

RAPID LEAD TIMES

Our rapid lead times mean we anticipate the customer’s timing needs, ensuring a quality product is produced as quickly as possible.

We utilize a number of ways to shorten lead times including:

- Laser cutting — We employ both flat and five-axis cutting to reduce development time and tooling complexity.

- High-skilled technicians — With decades of experience making parts, all of our technicians are cross-trained, so every aspect of producing a part is considered within each step.

- Tooling — Our full in-house machine shop works with the end part in mind so that any tooling modifications can be made quickly.

- Simultaneous programming and manufacturing — CNC programming, tool design and manufacturing, material acquisition, blank cutting and other preparations are all undertaken on parallel paths to facilitate short lead times.

- Simulations — We simulate tools prior to cutting to prove out designs and reduce wasted efforts, saving you time and money.

QUALITY

Fast turnaround times and competent staff mean nothing without a quality product. We understand that the quality of the part is of the utmost importance to the ultimate success of the product.

At Technique, Inc., we’re proud of our ISO 9001:2015 registration. We also integrate our quality management system into every aspect of our process.

We’re committed to producing the highest-class parts possible. We strive to not only meet the requirements of the print, but also to produce parts that are clean, with minimal tooling marks, shipped in a way that protects them from scratches and other blemishes.

- A three-part layout inspected to customer print (we create a print from your CAD model if one is not available)

- Plating/coating certification

- Material certification

- All other certifications as required by the print